The 15-Second Trick For Sheroz Earthworks

The 15-Second Trick For Sheroz Earthworks

Blog Article

5 Easy Facts About Sheroz Earthworks Shown

Table of ContentsThe Only Guide to Sheroz EarthworksGetting My Sheroz Earthworks To WorkAn Unbiased View of Sheroz EarthworksThe Definitive Guide to Sheroz EarthworksOur Sheroz Earthworks IdeasSheroz Earthworks Can Be Fun For Everyone

Today, Smart Building and construction Remote connects over 700 machines on jobsites to offices, conserving countless hours previously invested by jobsite supervisors, land surveyors and designers travelling from offices to jobsites. To summarise, the first 10 years of Komatsu's intelligent maker control have been marked by a years of unique advancement, continual understanding and development with consumers.

Below's to the following 10 years! Content generated in organization with Komatsu.

In the rapidly developing world of construction, accuracy and performance are crucial. 3D machine control, a system that utilizes general practitioner and other sensing units to lead machinery with identify precision, is revolutionising the market - https://au.enrollbusiness.com/BusinessProfile/6851844/Sheroz%20Earthworks. From its very early days of 2D guidance, this innovation has progressed dramatically, making jobs that when called for hands-on treatment currently feasible with minimal human input

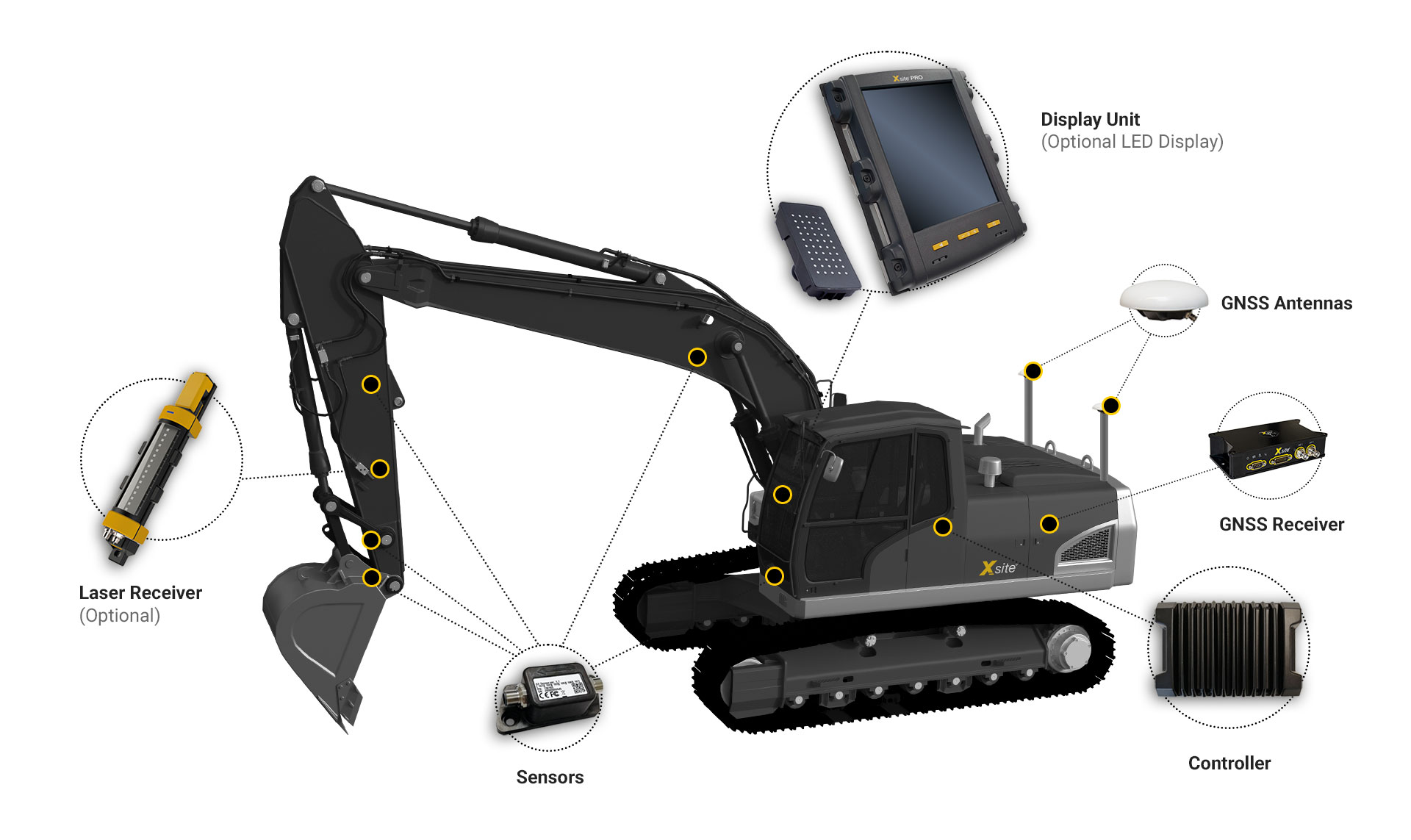

At the core of any kind of 3D equipment control system are GNSS receivers and antennas, capturing satellite signals to determine the device's precise area. Onboard computer systems and control boxes procedure this data and interact with the equipment.

The 10-Minute Rule for Sheroz Earthworks

This includes establishing GNSS receivers, adjusting sensing units, and setting up the equipment control software program. As soon as established, the system is incorporated with existing machinery for real-time modifications and advice. The magic of 3D device control depends on its real-time information collection and handling. GNSS and various other sensing units continuously collect placement data, which is fixed for mistakes to provide trustworthy and exact assistance.

Individual interfaces offer real-time updates on the equipment's position and essential modifications, making sure precise control. In building, 3D equipment control is used for earthmoving, grading, paving, and excavation, making certain jobs are completed to precise specs.

Top Guidelines Of Sheroz Earthworks

3D device control dramatically increases performance by minimizing rework and reducing material waste, bring about quicker and much more cost-effective task completion. The modern technology ensures every job is implemented specifically as intended, leading to constantly high-grade job. Among one of the most engaging benefits of 3D equipment control is the considerable cost financial savings it supplies.

Gas intake is optimised due to the fact that machines run much more efficiently and prevent unneeded motions. By decreasing human error and restricting direct exposure to dangerous settings, 3D device control improves worker safety and security and reduces crashes.

From building and construction to mining, this innovation makes sure tasks are carried out precisely and safely, lowering expenses and boosting results. As improvements continue, the potential for 3D maker control to additionally boost productivity and security grows. Welcoming this innovation is vital for sector experts seeking to stay affordable and attain the Extra resources greatest standards in their projects.

Sheroz Earthworks Fundamentals Explained

Discover the future of precision and performance currently! Additionally, take a look at our most current YouTube video on the FJD H36 Electric Motor Control System to see the innovation in action: Watch now.

For many years, we've seen operators with great deals of experience do some outstanding points with their makers. Maybe they have an eye for changes that improve precision, or probably they recognize which functions of their machine to make use of and when to increase productivity or performance - https://zenwriting.net/sherozau/sheroz-earthworks-pty-ltd-and-sheroz-hire-pty-ltd-est. But with today's developments in heavy tools modern technology, even experienced operators can benefit from a real-time assist to enhance their day-to-day performance (trimble parts).

This is where equipment control systems element in. Some excavators come with machine control systems that direct the driver through features to automate the digging process.

The smart Trick of Sheroz Earthworks That Nobody is Discussing

With this included precision, rework is virtually gotten rid of, permitting the driver to finish the project on time and relocate to the following task. For those working with hazardous or tough jobsites, remote-controlled remedies open new opportunities. This outstanding add-on allows you to run an excavator from a range in locations with hazardous materials (like in a potash mine) or poor ground conditions (like mud).

Device control systems supply valuable benefits to greater than simply excavator operators. On-board evaluating apps for wheel loaders, for example, are preferred due to the fact that several are so simple to make use of. On-board considering makes fast job of accurate packing. If you have actually a truck can be found in with a target of 23 loads, your driver can fill their container and dynamically evaluate itoften without also being fixed.

This suggests the driver can see the specific weight of the load they're about to unload (trimble gps). On-board considering provides real-time understanding into the pail's tons to make overloading, underloading, reweighing and waiting times a distant memory. Volvo Construction EquipmentIf they dump 12 lots on the first pass, the next pail needs to evaluate 11 loads

6 Simple Techniques For Sheroz Earthworks

A lot of operations utilize an on-board considering app to ensure that the lots is precise prior to they send their trucks to the scales, which is very important since the range weight is what's utilized for payment and invoicing functions. A number of makers include some kind of weighing program on their loaders. Some also have functions that allow companies to keep an eye on and regulate the overall tons of numerous vehicles.

Report this page